For many commercial property owners, a roof is something they only have to worry about when it leaks. While this makes sense for many things in life, it’s the most expensive way to go about commercial roofing. The decisions made about a commercial roof, from what material goes on top of the building to how often someone checks on it, cumulatively render predictable, steady payments or unexpected, unbudgeted blows to finances.

The truth is that commercial roofs are not like residential roofs. They’re bigger, flatter, and they take much more abuse from the sun shining on them throughout the day. A pitched roof is designed to help shed water to protect the interior of a home. Conversely, a commercial facility sits beneath a flat or low-slope roof, meaning water is more likely to pool than run away from the building. This means everything from installation to maintenance and replacement operates differently.

Material Decisions That Matter

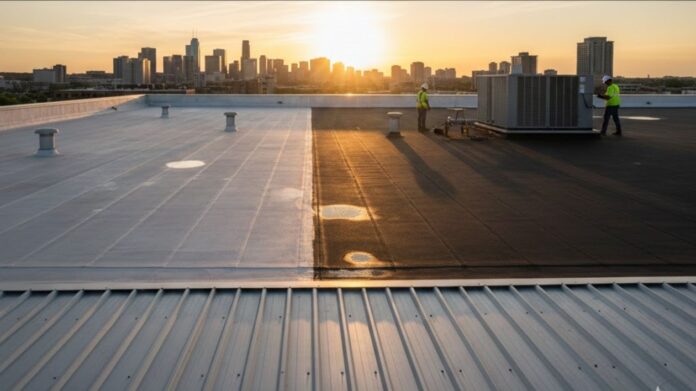

In years past, material options were limited. Nowadays, it’s incredibly easy to get overwhelmed by what differentiates offerings like TPO, EPDM, PVC, modified bitumen, and metal roofing. The first decision most people make is to go with the cheapest option; however, this does not often provide the best value over the life of the building.

For example, TPO roofing is popular among those looking for cost-effective solutions. This reflective roofing works in locations where air conditioning is mandatory for most of the year. However, not all TPO products are created equal. Thinner TPO is less expensive but vulnerable to punctures and does not last nearly as long as its thicker counterparts. To upgrade the membrane thickness, however, costs extra upon initial installation but could buy years on the back end. For a buyer looking at total cost of ownership, this latter option is preferred, but most initial quotes do not reflect this reality.

Then there’s EPDM, the black rubber roofing, which is ubiquitous on commercial rooftops. The installers have worked with EPDM for ages, and while the actual membrane is durable, the seams where two parts meet become problematic over time. Furthermore, these seams can only be sealed and inspected so much; a roof that has fewer seams (either large pieces or properly installed pieces) will have fewer vulnerability leaks in its future.

Lastly, metal roofing may be more expensive upfront than a membrane system; however, with additional maintenance, metal can last 40 years or longer, and for a company planning to remain in one building for decades, now it adds up. For someone who plans to sell after ten years? Not so much.

The Installation Quality No One Sees

Where businesses lose money and never realize it is in the realm of installation quality of their commercial roof. Commercial roof replacements must be made due to poor installation showing up as membrane failures that cause drafts, subsequent water damage and ruin insulation, this is expensive and should not happen due to poor scheduling or other factors.

It’s all about the details: how the membranes are attached to the deck and each other; whether the seam welds and glue are strong enough; if there are proper flashing around penetrations like plumbing and exhaust systems. These are things that business owners cannot see and assess upon roof completion, which means a reliable commercial roofing company must field quality inspections since these details can cut corners while no one is looking.

Additionally, drainage factors come into play during installation that can determine how long a roof will last; water sitting on top of membrane applies unnecessary pressure. If proper drainage exists (a roof deck’s slope, even on a “flat” roof, to push water toward drainage), then the water has a route out of reach. Poorly placed drains or a lack of sloped roof means pooled water weighs down on the membrane while decaying it faster than anticipated. This costs a fortune if done improperly instead of getting it right from the start.

Maintenance Programs That Avert Disasters

Most roofs fail because people forget to even check them out, commercial roofs fail because it wasn’t supposed to happen. When business owners wait for a leak to create buckets in their space before doing something about it, it’s too late; a failed roof is now an unsuccessful budget line as well.

Checking a roof twice per year, once in spring and once in fall, allows any minor issues that occur to be solved before they become major disasters requiring expensive repairs. Catching them when they’re small allows expenses to be manageable; if a small puncture occurs, easy, it costs less than $100 to patch. That same puncture becomes a section replacement of thousands if left to fester for months as water leaks into the insulation and decking beneath.

Furthermore, proper maintenance keeps warranties intact as well. Most commercial roofs come with some kind of warranty that requires semi-annual maintenance to maintain integrity; without upkeeping it, which costs money in operation expenses, an unhappy buyer puts themselves at risk in case something happens within that timeframe. However, business owners often skip annual inspections thinking they’re saving costs, but they’re just voiding any protection they think they’re maintaining.

The other thing maintaining does is going beyond lifespan expectations of a roof. A commercial roof expected to last 20 years can become 25 – 30, with proper maintenance in terms of taking care of seams, caulking around gaps and scheduled inspections. All of this equals savings by delaying capital necessary for replacement; most business owners don’t want to change their roofs more than they need to.

Timing Replacements Before There’s an Emergency

The most expensive way to replace a roof is when water is pouring through the ceiling tiles and creating destruction inside the building as business operations are halted indefinitely while safety measures are taken and then repairs begin.

When there are leaks everywhere, and word spreads about company’s poor facilities, now there isn’t enough time to compare contractors and find the best price. Emergency replacements get installed hurriedly, and they cost more because of it.

When business owners plan out their replacements ahead of time, they can avoid rush jobs. They can plan around seasons when business will be slow; they might even find financing options that wouldn’t have been available under duress.

Additionally, another factor that contributes to emergency replacements is lost business opportunity. When an office must shut down because it’s emergency repairs are four days, or four weeks, long overdue, then potential revenue is lost. Inventory might be destroyed; employees still need compensation regardless of where they cannot work inside a facility; having this kind of downtime can exceed costs more than finding feasible replacements without issue.

Energy Savings Change Long-Term Numbers

More than most business owners anticipate, energy costs have everything to do with their commercial roof. A dark roof absorbs heat throughout the day and, in turn, forces whoever runs their air conditioning day after day for hours. A reflective roof sheds heat, and makes air conditioning less necessary day after day for months on end, and saves subsequent costs year after year.

It adds up; it’s not small. Research shows that reflective roofing significantly reduces cooling costs by 10%-15% during peak hot months, which definitely matters when numerous units run all summer long across many companies’ rooftops. This is where roofs pay off over 20 years, a lower installation price with higher-upfront materials may lead those companies to have better cost per value proportions than companies who made short-term roofing choices.

Insulation works similarly; better insulation equals more retention against extreme temperatures over time. This leads people to spend more upfront for better grades but ultimately saves them money thanks to no leaks from below over time or excess energy costs down the line, not factoring into initial cost projections as well, the ROI always pays off.

What Truly Protects Investment

The general theme here, proper decisions regarding commercial roofing, comes down to what’s going to work best for long-term investment purposes rather than short-term capital expense savings today that could mean increased costs tomorrow through negligence or excess oversight, as anyone would do personally.

Decisions that seem easy now, like material selection, aren’t material when they reduce worth-of-value lifetime assessments; instead, material selection matches alongside quality installation counts match trade offs that prove why it’s more feasible to look at projected replacement needs rather than pretending it’s going to last forever every few years down the line.

Ultimately, keeping that roof over one’s head isn’t just protecting what’s inside; instead, it protects every asset inside, from equipment to inventory, and allows operations personnel to function without worry as long as someone else makes cheap commercial roofing decisions elsewhere. What puts businesses with consistently low-cost effective solutions apart from high maintenance concerns lies in proper upkeep investment.