Efficiency and quality have always been paramount in competitive industries, particularly within assembly processes. The quest to achieve high precision and speed is not just about improving operational efficiency; it transforms product quality and market responsiveness.

Automation is pivotal in this transformation, offering substantial benefits for businesses willing to adapt and innovate. By embracing the dual advantages of automation, companies can significantly enhance both their productivity and the reliability of their products. The journey towards automating assembly processes, characterised by the strategic integration of technology, marks a significant shift in manufacturing paradigms.

The Evolution Of Assembly Automation

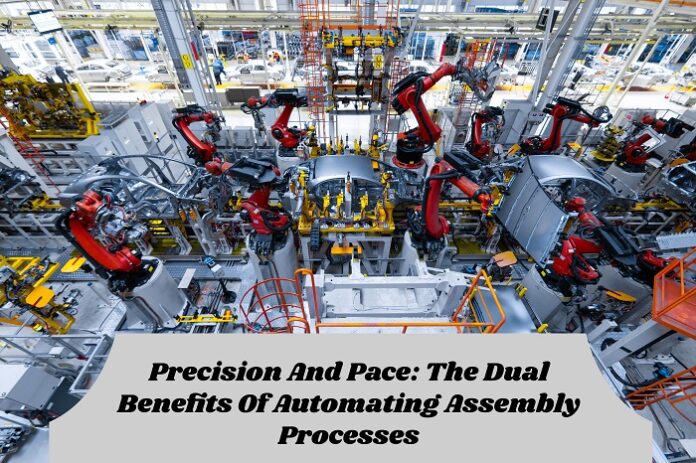

Historical advancements in automation have significantly reshaped the manufacturing sector. The journey from manual assembly to mechanised and, eventually, fully automated systems illustrates a relentless pursuit of greater efficiency. One notable example of this evolution is the adoption of linear vibratory feeders in assembly processes. These sophisticated devices, designed to orient and feed parts to assembly lines, epitomise the shift towards higher precision and efficiency.

Today, businesses of various sizes harness technology, including linear feeders, robotics, and AI-driven systems, to reach new heights of precision and speed. Embracing these innovations allows companies to streamline their operations and position themselves as leaders in industry innovation. Investing in such technologies ensures that businesses remain competitive in an ever-evolving market, demonstrating the profound impact of automation on the manufacturing landscape.

Understanding Precision In Automated Assembly

Precision in automated assembly is about executing tasks with exceptional accuracy, a feat that requires the integration of advanced robotics, sophisticated computer vision systems, and intelligent artificial intelligence algorithms. For businesses aiming to elevate precision, prioritising investments in these cutting-edge technologies is crucial. Such an approach elevates product quality, significantly reduces material waste, and enhances the reliability of the manufacturing process. Implementing these technologies involves careful planning and investment but positions companies as field leaders. Precise automation extends beyond traditional manufacturing sectors, permeating even into left-field industries like the cannabis sector. The invention of automated pre-roll machines blends advanced robotics with meticulous accuracy. These machines swiftly craft infused pre-roll joints with unparalleled precision, surpassing human capabilities.

Businesses should comprehensively analyse their current operations to identify areas where such precision-enhancing technologies can be most beneficial. Additionally, seeking partnerships with leading technology providers can offer access to the latest innovations in precision automation, ensuring continuous improvement and sustainability in a competitive market.

The Speed Advantage: Efficiency And Productivity

Leveraging speed through automation transcends achieving faster production rates; it embodies the capability to swiftly meet changing market demands with flexibility and efficiency. Businesses should identify and target repetitive, labour-intensive tasks for automation, freeing human workers to focus on more strategic, complex tasks that add significant value to the operations. This shift not only boosts overall productivity but also extends operational capabilities beyond traditional working hours, drastically cutting down production timelines and enhancing the ability to respond to customer needs quickly.

Establishing a robust automation strategy requires thorough planning and execution, including selecting appropriate technologies and retraining staff to manage and maintain automated systems. Companies are encouraged to gradually implement automation technologies, allowing for adjustments and optimisations that maximise efficiency and productivity gains.

Integrating Automation: Challenges And Solutions

Navigating the challenges of integrating automation into assembly processes, such as substantial initial investments and workforce retraining, demands a strategic and measured approach. Adopting scalable automation solutions provides a pragmatic pathway, enabling businesses to implement technology incrementally. This strategy controls financial exposure and facilitates a more manageable transition for employees.

Forming partnerships with technology providers that offer comprehensive support and training services is vital. Such collaborations can significantly smooth the integration process, ensuring businesses seamlessly transition to automated operations. Moreover, it’s beneficial for companies to engage in ongoing dialogue with their workforce to address concerns and provide reassurances about the positive impact of automation on job security and work quality.

Future Trends In Assembly Automation

Keeping pace with future trends in assembly automation, such as the adoption of collaborative robots (CoBots) and the integration of the Internet of Things (IoT), is essential for maintaining a competitive edge. To fully capitalise on these advancements, businesses should invest in adaptable automation technologies capable of evolving with the industry.

Actively participating in industry forums and establishing strong relationships with technology partners are effective ways to stay informed about emerging trends. These steps enable companies to be proactive rather than reactive in the face of new developments, ensuring they can continuously refine their assembly processes and maintain technological leadership in a rapidly evolving manufacturing landscape.

Making The Shift: Considerations For Businesses

The decision to automate assembly processes warrants thorough consideration of numerous factors, including a detailed evaluation of existing operations and the anticipated return on investment. Conducting an in-depth analysis to pinpoint processes that stand to gain the most from automation is a critical first step. Equally important is the selection of technology partners whose expertise and track record in delivering effective automation solutions align with the company’s needs.

These partnerships are instrumental in navigating the transition to automation, ensuring that investments yield measurable efficiency, productivity, and competitiveness improvements. Businesses are encouraged to approach this transition strategically, focusing on long-term benefits and sustainability to navigate the shift towards automated assembly processes.

Automating assembly processes offers significant advantages in terms of precision and speed, driving improvements in product quality and operational efficiency. By embracing automation, companies can position themselves for success in an increasingly competitive and dynamic market, ensuring they remain at the cutting edge of industry innovation.